Shelf life models

Models to predict shelf life in relation to temperature and other parameters have to be adapted to the specific spoilage characteristics of each individual product. In this project, we have selected one fruit (bananas) and two meat products (vacuum-packed Irish lamb saddles, pork minute steak in modified atmosphere packaging) for detailed modelling analysis, in relation to our field tests.

Meat products

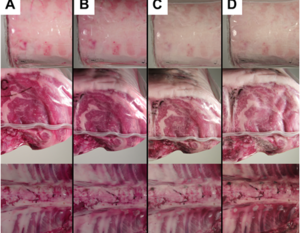

Changes in sensory attributes in relation to storage temperatures were evaluated by trained food tasters. The following parameters were evaluated for both of the selected meat products: meat colour, meat juice colour and volume, gas formation, texture and overall appearance. The results from the sensory evaluation were summarized in a model for each product [![]() 1].

1].

The model enables us to predict the effect of temperature deviations. For example, an increase in the average transport temperature from 2°C to 4°C reduced the shelf life by a value between 21% and 30%.

Bananas

The time span until the onset of a colour change of bananas from green to yellow is named “green life”. The green life was measured by a spectral analyser in laboratory tests for different storage conditions with regard to temperature, air humidity and atmosphere composition [![]() 2].

2].

With the measured temperature curve as an input, the model can predict their resulting effect on the green life. The green life loss per time unit is calculated after each measurement interval and subtracted from the initial value. Thereby it is possible to calculate the effects of a slowed cooling process, which can be caused by blocking of the airflow due to inadequate stowage of the pallets inside the container.

Greenlife of bananas in relation to storage conditions after harvest

|

Condition |

Duration of green life |

|

13°C, normal atmosphere |

31.9 ± 5 days |

|

18°C |

15.5 ± 4 days |

|

18°C, CO2 increased to 5% |

plus 11 days, compared to CO2 <2% |

|

18°C, humidity reduced to 55% |

minus 7 days, compared to 98% |

|

10°C |

chilling injuries after 8 hours |

(Greenlife measured after to 14 days of sea transportation at 14°C)

Relevant publications

- Jedermann, R.; Mack, M.; Kreyenschmidt, J.: Intelligent containers for the entire supply chain - Monitoring the product quality and temperature of meat products along the supply chain. In:

Fleischwirtschaft International, 2014, Vol. 28 (2), pp. 24-28.

Fleischwirtschaft International, 2014, Vol. 28 (2), pp. 24-28. - Praeger, U.; Linke, M.; Jedermann, R.; Moehrke, A.; Geyer, M.: Effect of storage climate on green-life duration of bananas. In: 5th International Workshop Cold Chain Management, Bonn, Germany, University Bonn, 2013. [

pdf]

pdf] - Mack, M.; Dittmer, P.; Veigt, M.; Kus, M.; Nehmiz, U.; Kreyenschmidt, J.: Quality tracing in meat supply chains. In: Philosophical Transactions of the Royal Society A, May/June 2014, Vol. 372(2017), 20130308. DOI:

10.1098/rsta.2013.0308

10.1098/rsta.2013.0308