Preliminary work

The idea for the project "Intelligent Container" was initiated by the ![]() Collaborative Research Centre SFB 637 "Autonomous Cooperating Logistic Processes". Twelve institutes of the University of Bremen were funded by the

Collaborative Research Centre SFB 637 "Autonomous Cooperating Logistic Processes". Twelve institutes of the University of Bremen were funded by the ![]() DFG from 2004 to late 2011.

DFG from 2004 to late 2011.

The SFB637 started with research of the required theoretical basics to implement autonomous logistic processes on objects, such as cargo equipped with sensors, containers or trucks. [![]() Projectflyer 2006]

Projectflyer 2006]

Demonstrator

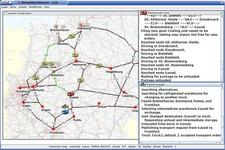

In 2006, a first demonstrator for dynamic route planning was established as result of cooperation between several partner institutions (IMSAS, ITEM, ComNets, BIBA, TZI). The intelligent container received temperature data from wireless sensors within the cargo compartment. The data was analyzed based on a product specific shelf life model. Every transport was represented by a software agent running on a background server platform. If a quality problem is detected, the agents start to negotiate with each other to find a solution to minimize the risk of losses, e.g. by swapping the means of transportation or by allocating the good to another destination point.

Algorithms

One goal of the project was to implement an autonomous decision platform on embedded systems with limited resources, such as processing power, memory and battery capacity. Various algorithms for evaluation of sensor data were developed and optimized for our target platforms, such as the computing platform of the intelligent container or event wireless sensor nodes. The list of available algorithms contains:

- Spatial interpolation to predict a temperature profile with a reduced number of sensors

- Shelf life models to calculate the effect of temperature fluctuations on the quality of sensitive food,

- Neuronal networks to detect sensor faults and deviating transport conditions

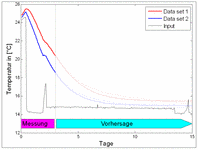

- Models to predict the further course of temperature based on the recent measured values

The results of the SFB637 are documented in numerous publications.

Field tests

From 2008 to early 2010 the first field test took place in the context of a SFB637 transfer project. The system was tested on actual shipments in containers and trucks for the first time in cooperation with the partners ![]() DOLE,

DOLE, ![]() CARGOBULL TELEMATICS and

CARGOBULL TELEMATICS and ![]() RUNGIS EXPRESS which is a subsidiary of

RUNGIS EXPRESS which is a subsidiary of ![]() CCG. The collaboration with industry partners will continue in the context of the Innovation Alliance.

CCG. The collaboration with industry partners will continue in the context of the Innovation Alliance.

Two containers loaded with bananas were fully monitored on their way from a farm in Costa Rica until their arrival in Hamburg for a test carried out in 2009. Both containers were equipped with 20 wireless sensors and a gateway to collect the data and transmit it over the satellite system of the ship. [![]() Press report].

Press report].

Further experiments were conducted with the support of ![]() LogDynamics Labs in the test truck of the University of Bremen.

LogDynamics Labs in the test truck of the University of Bremen.

Further cooperations 2006 to 2009

In collaboration with the Dutch manufacturer Ambient Systems of sensor nodes, a shelf life model was implanted on commercially available sensor nodes. [![]() Press report].

Press report].

TurboTag data loggers have been provided by Sealed Air Corperation, which can be read wirelessly by an RFID interface.